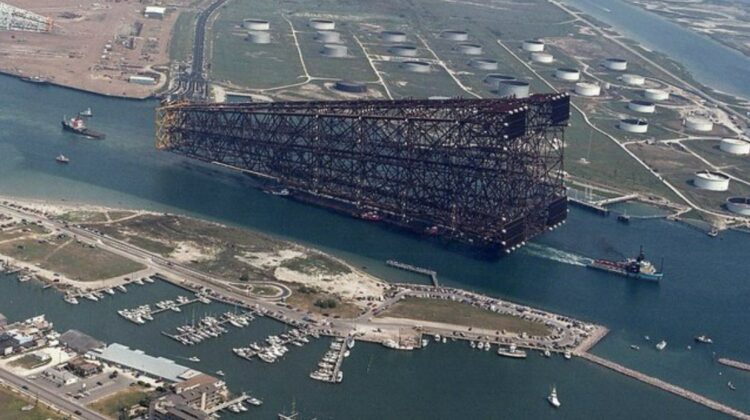

The base of an oil platform, also known as the jacket, is a massive steel structure that is anchored to the seabed. It provides a stable foundation for the platform deck and all of its equipment.

Before being towed out to sea, the jacket is constructed in a shipyard. It is made up of a series of interconnected legs, trusses, and braces. The legs are driven into the seabed to anchor the jacket in place.

The jacket is then towed out to sea by a team of tugboats. This is a delicate operation, as the jacket is very heavy and unwieldy. Once the jacket is in place, the platform deck is installed.

The platform deck is a large, flat structure that houses all of the equipment needed to drill for and produce oil and gas. This includes the drilling rig, processing equipment, and living quarters for the crew.

Once the platform deck is in place, the platform is ready to begin drilling for oil and gas.

Here is a more detailed look at the different parts of the jacket:

- Legs: The legs are the vertical supports that anchor the jacket to the seabed. They are typically driven into the seabed using a pile driver.

- Trusses: The trusses are horizontal and diagonal supports that connect the legs together. They help to strengthen the jacket and make it more resistant to waves and currents.

- Braces: The braces are short, diagonal supports that connect the legs and trusses together. They also help to strengthen the jacket and make it more resistant to waves and currents.

The jacket is a critical component of any oil platform. It provides a stable foundation for the platform deck and all of its equipment. Without the jacket, the platform would not be able to operate safely and efficiently.

Leave a Reply